We can provide the right solution for you. With intelligent technologies for movement,we ensure efficiency and flexibility in warehousing.

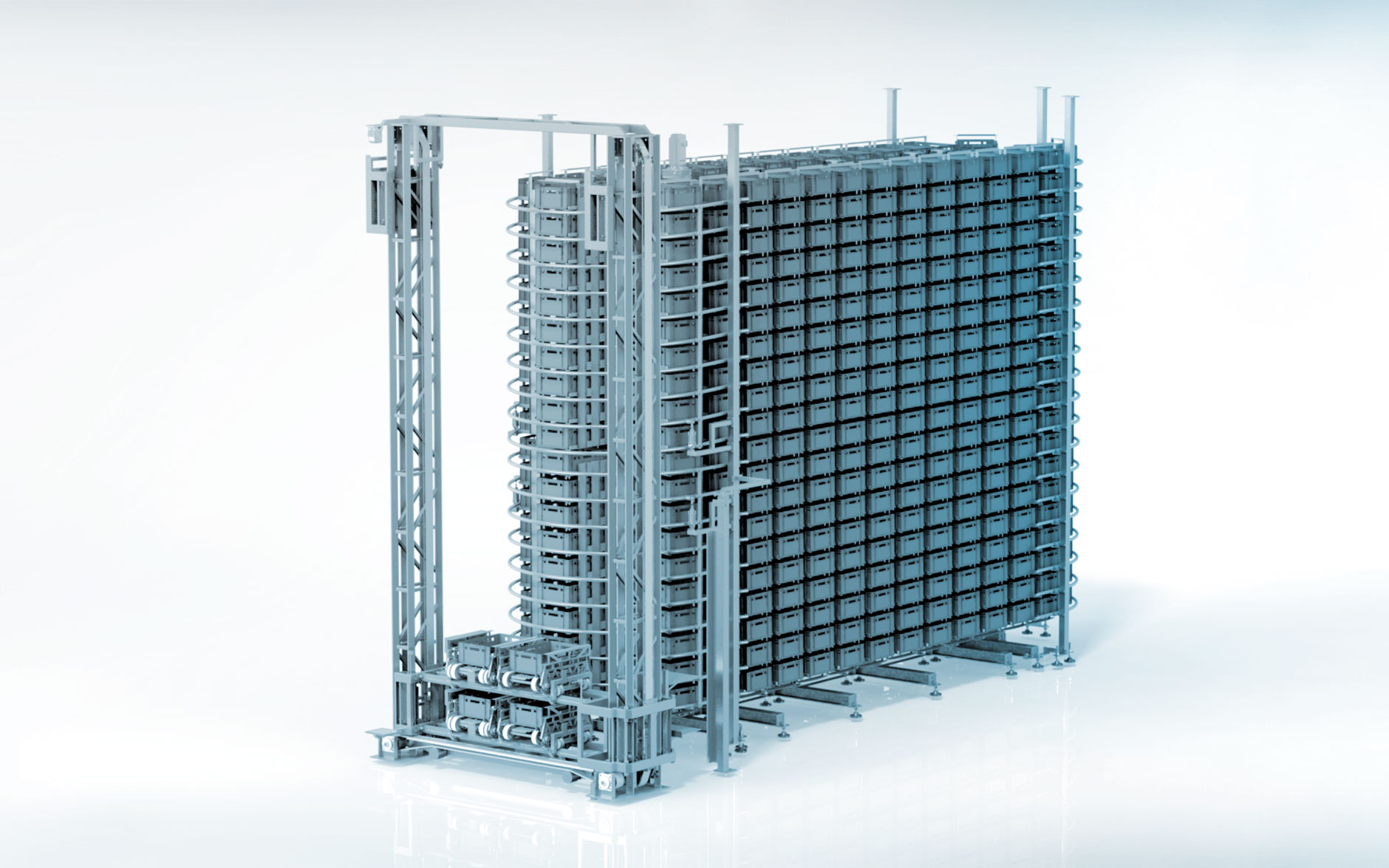

Empty-crate buffer for plastic crates – Automation for empty crates

Our empty-crate buffer will save you space, time, and will reduce operating costs. The maximum storage input/output speed with a spatial utilization of up to 7.2 m height provides distinct advantages. The crates are stacked with their bottoms upwards and cannot be soiled on the inside when on top.

Your storage remains clean because cleaning is optimized due to the free floor space. Handling of slightly damaged or slightly deformed crates is not a problem. Extensions are possible as desired thanks to the modular design. Thus you can react flexibly to increased demand. The capacity of the empty-crate buffer is 160 crates per m² for all common plastic containers of the food industry that have a base dimension of 600 x 400 mm. The empty-crate buffer can be also be configured for other crate dimensions.

Picking systems – Ideal partner for production and dispatch

The crate picking system KKS serves the short-term, chaotic storage input and subsequent sorted storage output of full crates. The KKS is set up as a carousel storage system with rotating units. The KKS allows for a high number of crate movements and a high storage capacity with unmanned operation.

Storage and retrieval devices for plastic crates – Automatic storage input/output

Storage and retrieval devices handle the automatic storage input and output of conveyed materials in high-bay storages and the charging of flow racks up to 6 m construction height and 50 kg load-bearing capacity. For application under normal and deep-freeze temperatures. Storage and retrieval devices are a basic component in logistics and goods movement. They allow for enormous competitive advantages and saving potentials by gaining time while simultaneously cutting costs.

Flow rack for full crates – Great performance with minor space requirements

It consists of roller conveyors that are mounted in several horizontal and vertical levels. This solution is ideal for intermediate storage with quick fl ow and for picking piece parts for orders.